The Zeiger Family Boat Building Page

Frequently Asked Questions about Dave and Anke's Luna

Dave Zeiger © 2007 - 2017

Is Luna a Bolger Design?

What are the basic differences between Bolger AS-29 and your modified version?

What? No engine?? What are you, some kind of purists?

Right. What’s a yuloh?

How is Luna rigged?

Would you make any changes to the rig?

Under what conditions will you choose to sail?

How do you sail Luna?

Are you happy with the Junk Rig?

But what about windward performance?

Are those leeboards, or what?

But aren’t they a) noisy, b) weed-collectors, and c) ugly?

Is it true you’be broken several?

How is the interior laid out?

Why wood for fuel?

What about a head?

How about other waste?

Cheap seems to be a theme, with you — how do you finance your lifestyle?

What did building Luna involve?

What’s with the copper sheathing?

Do you have electric power?

Do you have any regrets?

But are you happy with her?

Is Luna for sale?

No. Phil Bolger developed a hull form he calls Advanced Sharpies (AS), and Luna embodies his principles (as closely as I could follow). Inspired by the sharpie hull form, they inherit a sharpie’s narrow beam for their length, hard chines and continuous rocker.

Bolger hardened the chines to fully rectilinear. This makes for easy construction, makes the entire hull length laterally resistant and maximizes initial form stability (on a given overall beam) and interior volume. A perk is that lockers low in the hull are essentially rectangular (vs. the usual triangular stowage along the turn of the bilges).

He increased rocker to bring the forefoot and stern well clear of the water.

Pros: Much easier construction than V, U, step or blister bows. When upright, the waterline shortens, allowing nimble tacking. When heeled, the waterline lengthens for greater hull speed.

Cons: When upright and wave angle matches the forefoot angle, it pounds (this mostly occurs when anchored with a lot of high windward fetch, and shouldn’t hurt the boat if she’s well-built). The ‘bow transom’ in part, reduces under-bow surface area to reduce pounding. If it gets bad and we’re too lazy to move, we tie a fender athwartships under the bow, which cuts the noise by about half. This is not as much of a problem as one might expect; we’ve only had three or four loud nights in ten years. Our next boat will have the same type of bow (we have a thick bottom forward, and are considering foam sandwich for the next).

He matched hull curvature in plan and profile views along the right angle chine (as seen in end-view — the bow transom contributes to this). This produces a symmetrical chine, with pressure equalized on either side; water is not forced across the chine, improving tracking and speed. This is an improvement over traditional sharpies, whose bottoms push water aside faster than their sides do, leading to a pressure differential on either side of their chines.

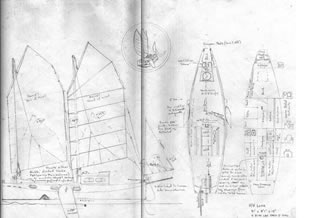

Click on image for larger view.

AS hulls I know of from Bolger are OLD SHOE (AS-12), MICRO (AS-16), AS-19, LONG MICRO (fat AS-19), MARTHA JANE (not officially an advanced sharpie, but essentially an AS-24), AS-29, LOOSE MOOSE II (AS-39). More recently he's designed a larger one, at about 55 feet, as well. Some of these designs, such as the MARTHA JANE, stray a bit from strict AS design (AS-19 is, I think, the purest example of the form), but all are heavily influenced, and each is a tried-and-true design from a master’s hand. JESSIE COOPER is not an AS, but gets honorable mention as the immediate predecessor to the AS line.

Overall, the AS hull-form delivers maximum bang for the buck for the DIY Boatbuilder.

What are the basic differences between Bolger AS-29 and your modified version?

Overall dimensions were increased to maximize sheet plywood dimensions (AS-29 is 29'6" x 7'9" x 13" @7300 lbs, Luna is 31'0" x 8'1" x 13" @8300 lbs — add our guards and 4-5 inches of live-aboard bloat to that). The AS-29 fits in a 30 foot berth and is trailer-legal without a following or special permit, features we didn’t need.

After that, we designed our own deck and interior layout, rig and added external ‘off-centerboards’ and a kick-up, balanced, transom-hung rudder.

We sail engineless, so the transom doesn’t have a center-mounting for an outboard.

What? No engine? What are you, some kind of purists?

No, a less "pure" couple would be hard to find. We like sailing without an engine enough that it’s not cost effective to have a motor with its gas, tools, spares, fire suppression, maintenance, weight and space, noise and dependence on a fuel supply. That is to say, we're cheap and lazy (ironic, isn’t it?).

Most folks think that the motor is for when the wind kicks up, but OB motors are soon overpowered, while the sails are powering up to the point that you have to dump the excess (reef). Alternative propulsion is for flat-calms. That’s when we yuloh.

A yuloh is a curved sculling oar with a horizontal blade. It has a lanyard at the inboard, handle end fixed to a point straight down from the yuloh’s centerline, which allows an arc of side-to-side movement. The blade, at the other end, makes a ‘fallen leaf pattern’ (a shallow 4), with the leading edge angled down to about 45°. At each end of the stroke, the curved loom (inboard end pulled toward center by the lanyard) wants to "spill" the correct leading edge down to its new, downward angle for the return stroke. Perfectly balanced, all you have to do is rock back and forth. Imperfectly balanced (it’s that kind of world), you might have to help it a bit at the end of the stroke.

I get 1.5 knots at an "all day" pace, or 2 knots at a sprint. Most folks work too hard when they begin — twisting the yuloh, rather than letting the lanyard do it and putting a lot of effort into the stroke (anything over that 1.5 knots is an exercise, literally, in diminishing returns. With a fair current, you can cover a lot of ground. Don’t bang your head against foul ones. We can make progress into about 5 knots of headwind, but we’re better off sailing in any breeze that ripples the water.

Luna has the yuloh to starb’rd. We stand with the tiller loosely between our legs and nuance one way or the other (a few inches with both yuloh and tiller, same direction) for gradual turns. For more abrupt, or turn-in-place, kick the tiller from between your legs to the turn side, rotate the yuloh blade to vertical and shovel water with short, circular strokes (clear of the water on the return).

To make the yuloh, we look for a snow-bent spruce of the right size and curvature (I’ve read that 18° is optimal, but I just eyeball it). Thick end inboard, with a vertical, canoe-paddle handle whittled in (helps you assist the spill if the lanyard doesn’t quite do it). At the far end, flatten the sides (sides are 90° to the plane of the curve) and add blades. Our blade finishes about 10 inches wide (at the top, tapering to 8 inches at the end) x 2 ft long x loom thickness (at the top, tapering to about 1 ½ inches at the bottom). We round the forward face (or down face, if you prefer) and leave the aft face (upper face) flat. Goes pretty quick with a drawknife.

There are many fulcrum arrangements, but a large, open oarlock works. Use chafe gear, if necessary, and consider a lanyard from the fulcrum to the outboard loom.

Luna under yuloh power.

Luna is a three masted, junk rig cat-schooner. Her main and fores’l are of equal size (interchangeable). A small mizzen is set aft for balance, holding her nose up while underway, and serves as a riding sail at anchor.

We designed the sails as slightly modified ‘Hassler preferred sail form’ (we dropped the yard angle a bit). It features a large parallelogram with battens angled such that, when reefed, the sheetlets hang clear of one another. All battens are the same length (interchangeable).

The rigging is a bit of this and that. Running lines are the haulyards (three part) and sheets (six part, no euphroe — not as efficient, but no handling is necessary) are the running line. All lines are led to the cockpit, and the three sails, set on free-standing masts, are self-tending. The mains’l boom is at seven feet over the cockpit, ending four feet forward of the transom (sheets stay clear of the forward cockpit).

The mizzen has no haulyard and stays laced to its mast. To furl (when not underway or free to swing at anchor), we raise the forward end of its sprit boom to vertical, roll the vertical bunt of sail that forms, and spiral wrap it all with a light line led from the masthead.

Sails are of 6 oz Dacron. We sewed them with a Pfaff home sewing machine. Being flat-cut, they’re very easy to make. HINT: use staples instead of pins to secure your fabric until sewn.

Would you make any changes to the rig?

Yes. We plan to add down-hauls to the main and fores’l mid-battens. The tacks ride up while beating in heavy winds, spoiling the shape. At present we go forward to clip in a tack downhaul when necessary.

Also, the upper triangle (above the parallelogram) is lightly sheeted, relative to its area, and induces heavy twist when beating in strong winds (from half-reefed down, in gales or worse — conditions that find us scuttling for shelter). In our next rig, we plan to reduce the area aloft and yard angle to reduce unsheeted sail area.

Twist is exacerbated by the accumulation of purchase in the "bundle" as we reef (euphroes eliminate this problem). This is only a problem while beating, which sucks in high winds anyway. But if we must get to windward, we unclip blocks from lower sheetlets (first on is merely removed, second on is clipped to a becket on the upper block — maneuvers which require deck-work). Once deep reefed, with all purchase in the bundle, the problem disappears. To address this problem without euphroes, I’d like to add "star-drag" to our blocks. Friction can be induced, then, with the ability to drop purchase "out of the loop" and fully control leech shape.

Under what conditions will you choose to sail?

Beating becomes hard work at about 25 knots of wind. We’ll reach or run up to about 35 knots (but usually if we want to cover a long stretch quickly). We’ve been out in a few, short bursts of 50 knots, grateful for the junk rig. We pay attention to our downwind safety bearings.

Sea conditions make a big difference. No boats are at their best in short, steep seas. Luna will plow ahead under those conditions, but it’s slow going. We must have dipped our bow transom, but I’ve never felt it. Now that Scups, our dog friend is ‘dog-gone,’ we sail more efficiently at higher angles of heel (he hated that), to about 25°.

Our idea of optimal cruising is to linger in coves, with short hops in light winds and longer ones in fair winds up to 35 knots No sweat when we don’t have a deadline.

Sails reef by releasing the haulyard (usually don’t have to round up) — Bababababoom — drop as many battens as you wish into the bundle (held by lazyjacks). The sheet goes loose as the sail drops. Cleat haulyard, trim sheet — 'bye!

Luna beating at the end of a 25-knot squall with two panels down in each sail.

Flat cut junk sails develop camber by allowing and controlling twist. Battens are angled to the horizontal flow of wind, and share their point of rotation at the mast. The horizontal wind flows over sail segments that form the shape of an airfoil (this is one theory — check out turbulence or vortex generator theories). More twist increases draft (light and/or off wind); less twist reduces draft (higher, contrary winds). Hold your hands with spread fingers angled upward. Twist in, twist out; twist in, twist out. Picture the horizontal flow of air; see the airfoil. You go, Grasshopper!

On the wind, trim as usual, but with twist in mind. Sail her a bit broad (about 50° off apparent — she’ll move while stalled, so develop the feel for the "sweet spot" — I’ll bet pinching has a lot to do with the junk rig’s poor reputation to windward — Luna’s main-lowest-panel luff is the best visual indicator of stall). Trim the mizzen tighter to induce weather-helm, reduce fores’l or swing the boards forward. Vice versa for reducing weather helm. Adjust the cleated sheets (shake the fores’l) to keep the leech curves fair. In heavier wind, we reef fores’l first, and deeper than the main to ease tacks. Once balanced, lash the tiller a tad to windward and she'll self-steer.

Off the wind, jibes are no sweat, so we tend to broad reach for speed and higher inattention tolerance (though daydreaming leads to "blanketing" the fores’l for a sneaky 50% reef!). If we run, we sail "wing and wong" with equal sails (mains’l is "wing", and always kept down wind, fores’l is "wong" and sailed by the lee — you can actually broad reach this way.

With variable wind or course we sometimes trim the fores’l and mizzen for a beat (she’ll sail without the main as a cat-yawl, too) and leave the main free. On the wind, we trim the main by hand, or not. Off the wind, we sail under main and blanketed fores’l. Saves a lot of frenzy in the cockpit when things are tight!

Luna sailing in cat-yawl mode, before main was stepped.

Are you happy with the Junk Rig?

Absolutely. Over the years it dawned on us that we’d never met anyone who’d tried junk rig who switched away (short of going multi-hull). Count us IN! Ease of reefing, fail-safe nature, low maintenance, along with ready-to-go-at-any-moment status has us hooked.

But what about windward performance?

Windward performance is fully compatible with junk rig. New approaches are quite competitive. Western boats get to windward primarily by setting special sails (genoas, spinnakers, lappers, etc.) all of which may be flown with junk rig, if you’re willing to invest the energy. Personally, we trade some ability for KISS, but not a huge lot. In ‘07, we sailed over 1000 nautical miles (Alaska's inside passage) with less than 20 hours of fair wind!

Technically no. Leeboards only work on the lee side, and go ‘broken wing’ if dragging to windward.

Luna has "off-centerboards" — a rigid bar forms a slot that keeps them from winging out to windward, so they work on both tacks. They, like the sails, don’t need tending each tack. We saw the idea on a Bolger ex-DUGONG.

They have the advantage over internal boards of being cheap and quick to build and maintain, and don’t weaken/put a hole through the hull. We have the option of using the main haulyard to lift them clear of the slots if we want to dismount them for painting, or somesuch.

But aren’t they a) noisy, b) weed-collectors, and c) ugly?

a) No (firehose padding along the slot and rubber at the pin).

b) Sometimes, though seldom (like anything sticking down there, and way easier to clear).

c) Wanna step outside and discuss it? Just kidding; but seriously — de gustibus non disputandum est.

Is it true you’ve broken several?

I do confess it, though it’s my engineering and/or construction at fault, not the concept. There wasn’t a lot of info available to us when we started, so we’ve reinvented some flat tires. Solid boards, like the Chinese, Dutch and English have used on majorly large vessels, all work fine. Hollow boards (free flooding) should work fine, too, if engineered and built correctly. We cracked ours only in extreme conditions (design flaw allowed stress-loading at the forward edge), and even then we’re still using one of them (angled a bit further aft, it still works — fail safe!). Beyond a certain size of either kind, mechanical purchase is required, but that’s true of center- and dagger-boards, too.

Our latest (two layers of 2x10 angled slightly to one another with 35 lbs of lead ballast) are absolutely rigid. They’re heavy, but either of us can clear the bottom of the hull with no purchase, and two of us can stow it clear of the water.

The interior is divided, generally, into longitudinal "girders" of framed plywood webs that help stiffen the hull.

Aft is a large, standing head-room galley (9 feet of counter space) with a small, Jötul wood-range for cooking and heating (Cons: it’s a high traffic area (the two-foot gangway is comfortable for us two, but turns out to be narrow with company) and the trunk cabin forms a "heat chimney," pretty hot for whomever is cooking). A full-size, double sink was installed athwartships (this has worked out very well). Two hand-pumps; one pulling in seawater, the other fresh water from 5 gallon jerry-cans. The sinks drain via the only through-hull, above the waterline and under the board guard. The galley counters double as seats to form a pilot house of sorts. We can sit inside with 360° visibility and steer with leads to the tiller. "Bread-board" steps (retract into cabinets, port and starboard, for access to the under-cockpit stowage) lead to the cockpit.

Midships is the salon (6'6" long), with a settee across from a dinette table. The dinette can be made down into a double berth. The galley sole can be moved in to span the gangway, forming a platform with the dinette berth and settee (and bunk — great for slumber parties or big projects).

Forward is the large double berth, with a leanbank to port, clothing shelves over the foot and coathooks starb’rd.

Well, it grows on trees! It’s free, available throughout our cruising ground, smells good and provides very dry heat. We used to use propane for fast hot water, but it’s not much faster than wood, we have to buy it in town and it takes up another footprint on a small boat.

We gather wood about once a week with bow saws, racheting loppers and ax (takes about an hour) and target small diameter, standing-dead spruce, cedar and hemlock.

If we could find coal bricks, we’d like to carry 50 to 100 lbs as ‘health insurance’ (in case we both were down with flu or somesuch).

Just a honey bucket. We try to shit ashore for the most part, and have a tight-lid "fudge-bucket" for emergencies.

Showers can be spit-bath, over the sink and a basin, or use the stainless steel pesticide sprayer (bought new) to deliver spray in the cockpit or ashore. We found that solar showers don’t hack it for 99% of the year up here.

We burn paper products, mince compost for immediate disposal, compress washed or clean plastics (you can cram a week to a month into a single plastic mayo or peanut-butter jar) for disposal in town, crush cans and aluminum for recycling, sink (break first) or recycle glass.

Cheap seems to be a theme, with you — how do you finance your lifestyle?

At present, the general theme is to invest the money we don’t earn in free time. Thousands of dollars not earned equals hundreds of hours free to do whatever we please.

On the demand side, we try to keep our overheads low. Enginelessness, wood fuel, bulk food buys and wild foods, minimal rent (occasionally at the dock in towns), dryout (vs. haulout), inherent exercise and "social distancing" (we’re seldom ill) all help. But, dost think because thou art virtuous, there shall be no cakes and ale (or wine, chocolate, DVD rental, pizza, etc.)? We travel once every three or four years to Europe (visiting Anke’s family and friends), which swallows a year’s budget with ease. Altogether, we’ve been averaging about $6,000 per year over twenty years (includes intermittent boat building). We keep thinking that’ll drop when the "last boat" is built and equipped.

Supply side, we are fortunate to have the AK Permanent Fund Dividend, which puts a variable, but always hefty wad into our pocket ($1000 to $1700 per person per year, depending on market conditions). The rest we make up with occasional odd-jobs (and/or a major one every ten years or so).

I’m working on designing boats for sale (www.triloboats.com) and writing a novel, along with several other hopeful generators of micro-streams of income. Our goals are to afford catastrophic health insurance and move toward establishing a cash/cache/capital financial basis.

What did building Luna involve?

We built Luna in 1997 in Tenakee Springs, AK. Materials (fir ply, red cedar framing/chines/deck) were barged in on the one delivery that summer. We built outdoors (on a pile of sodden wood chips!) next to a structure we could use as a shop. We went cheap on the tarp shed and ended up calling it "Fatima of the seven veils."

Luna under construction beneath the tarps.

We started full time (averaging 10 hours a day) on 7 June, had a month of visitors, lost about a month to weather, shed maintenance, etc., and launched on 29 November. I call it four months. Hull was complete, interior roughed in, no rig, rudder, or boards.

Lofted (bottom curve in profile, and sheer curve in profile and plan), cut out all hull components and built the bulkheads and transoms.

Began with the bottom (I designed doubling plates on Luna’s lower hull that act as a longitudinal butt-block between the lower and upper hull, which really simplified construction). Bottom is three layers of ½ inch ply glued with Weldwood Plastic Resin Glue.

Turned the bottom over (with townfolks helping), inserted bulkheads and transoms, slipped side planking into the notch formed between plates and the bulkheads. Glued (3M 5200) and nailed (bronze ring-shank).

The deck we strip-planked from red cedar 2x2s cross-nailed (galvanized — bronze was too expensive). Should be strong enough to take a brown bear walking over the deck (don’t wanna field-test that!). Covered it with fiberglass cloth set in latex lagging compound and top-coated with aluminized, asphalt-based trailer paint (applied with roller, it stipples for great texture tread).

Foredeck under construction, showing 2x2 strip planking.

Painted the topsides with latex (no sheathing or resin coat). We’d seen ply skiffs finish this way left on the beach for years, that still looked good (needed paint, but ply was fine). Latex is cheap and easy to clean up, with no solvents to dispose of. In retro, might’ve sealed the ply with resin, first (no cloth), but it remains an option. Lately we’ve been admiring UV-stabilized house oil finishes.

Launched, again with the town’s help.

Launching Luna. We pivoted her to port and slid her down to the water.

We promptly moved aboard, slowing progress to a crawl. We fit her out over the next years (only actually sailing from 2000). I’d figure maybe another four months, total of full-time work stretched over four years.

Total cost was about $12,500 (pre-2000). Copper was $4000, rent $1500, sails $1250 (materials for two suits) the stove came to about $2000 (a long, sad story). We had the aluminum, main tabernacle and mastheads welded up for $500. I added 15% to cost for AK prices and getting to TKE, but it could easily have been 20% or more. Adjusted for standard construction (bottom paint, $500 stove, single suit of sails, wood tabernacle, no transport fees) and before rent, that’s $2000 to $2500 for the hull, interior with stove and rig.

The big savings came from Costco plywood at $18 per sheet of ½ in, 5-ply fir. L&S Cedar provided very high quality #2 and better red cedar at a very reasonable price.

What’s with the copper sheathing?

Luna has 1750 lbs of copper sheathing, reaching to well above the waterline. That’s her entire ballast. The 1/4 inch mid-plates provide grounding protection. Elemental copper provides non-toxic anti-fouling (produces an electrical field that growth doesn’t like (factoid alert! I read this somewhere — must be true!)... cuprous oxide, active ingredient in many common anti-fouling paints is toxic). We have to scrub it lightly two or three times a year, depending on various variables, but just dry out to do it. I figure that the copper paid for itself in haul-out expenses in the first two years. Lastly, if we ever get around to installing a lightening protection system, it’ll make great discharge plates.

We didn’t have the cash flow to order the copper sheathing (2000 lbs of sheet copper — mid-plates 1/4 in thick) in time to glue it on while the hull was upside down (the sensible thing to do). So we screwed it on with bronze square-drive screws, counter-sunk into the copper, between tides while Luna was on the grid. Don’t recommend doing it that way!

Yes. A 40W Kyocera solar panel charges a 126 amp-hour, deep-cycle battery. We have a floating system (not grounded to the sea or major metal) with socket- and nav light-circuits. We avoid most wiring by using stand-alone units with rechargeable NiMH batteries (VHF, GPS, interior lights (moved away from kerosene) flashlights, spotlight.

We’d like more generating capacity to run the computer (pigs out half our amp-hours in eight hours of run-time — a 12V to laptop voltage specialty inverter would help; shopping as I write). We lack deckspace for more PV panels, but may add pipe rail and/or a turgo wheel (anchored near a waterfall) and/or prop generator (anchored in streams or running). Another idea is to install thermocouples or GaSB (infrared optimized PV) cells around the woodstove. As sunlight diminishes in winter, the stove is running longer hours. Expensive wish-list, though!

Yes. We built her as an intermediate boat — one we could build in Tenakee, learn from and sail for a decade before building "the last boat." We thought she’d be a glorified camper-cruiser. She’s a little too glorified — if we’d known, we would’ve gone the extra hundred yards and fully met our wishes.

We’d like the following:

Yes, very. We DO plan to sell her and build our last boat, but it’s a hard decision. Addressing any two of that wish-list might be possible, but pretty soon it’s easier to build from scratch than retrofit. She’s a great boat, as is, for most of those interested in square boating, so why dig into her?

We sold Luna in August 2008. We now live aboard Slacktide, a new boat based on our Trilobyte design. You can purchase our StudyPLAN for her at our Triloboats Website here.

Mark and Michelle's

Boats:

Selkie

Forget-Me-Not

Roan

HOW CAN I SUPPORT THIS SITE?The information on this site is free to you, but not to us. Our cellular based Internet connection costs a good percentage of our total monthly income. The best way to support us is to become a Patron on our Patreon Page. That way, you get stuff for your contribution! Also, we earn revenue through purchases from our Store, ad links on each page, and Amazon.com pays us a commission on purchases from their site if you enter through our links on the Book List Page or on the blog. This applies whether or not you purchase one of our selected titles. |

|---|

©2019 Mark A. Zeiger